Cement production When it comes to cement, first of all a scientist

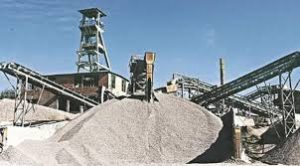

It came up who invented the first cement and in term was able to make cement by mixing different methods and gradually the whole world moved it Puri and India neighboring country of Bangladesh India in 1904 they invented the first cement factory in different countries except in different countries. -Factory can be found in foreign and different places of Bangladesh factory bus cement production first stone is not required if limestone is available then to make cement first limestone is needed then black type of stone is stored then red type of stone is stored Sand or red soil is a mixture of these four ingredients to make cement. Every ton of cement requires about 250 grams of silica. If there is no silica, then cement will not be made.

Nor will children be long nor can they be made to produce cement. When the cement is delivered to the factory, different companies or different trucks supply the raw materials of the cement, but even if the cement raw materials are bought very cheap, it costs a lot of money to carry them or take them from one place to another. Along with this, they are pounded through different machines and cement is made by mixing different ingredients. Once the cement is made, cement is produced in the morning through different sacks in different small and big shapes. Bangladesh now has a few more cement factories. There are cement factories in Narsingdi. Different areas, different big port areas, different cities, all cement factories can be seen, thousands of workers in cement nature

Working and benefiting economicallyThey are benefiting economically by working and they are benefiting in various ways and building cement factory is creating self-employment in Bangladesh and employment generation is leading to the development of a country and nation. So it is necessary to produce it so that most of Bangladesh will be economically prosperous and a beautiful state and nation will be formed. When the cement is made, when the complete cement is made, its upper part has a light brown color and is created like a substance. Pennies are made so that any granule is prepared and prepared in that way and approximately 40 to 50 kg in a bag of cement are kept in various stores through the factory and they are sold or the price of cement ranges from Rs. Tk 500 per sack of cement to build houses and houses as needed, large constructions, various pillars and other parts, cement is widely used, so cement is being produced in large quantities in Bangladesh and its use is increasing.